The Hidden Complexity Behind Every Robot

In modern factories — whether producing aircraft components or automotive subassemblies — robots are everywhere. They weld, assemble, inspect, and handle materials with increasing precision and autonomy.

But as automation spreads, so does the complexity of ensuring that every motion, enclosure, and safety function meets the strict requirements of CE Marking and the EU Machinery Regulation (2023/1230).

Behind every robotic work cell sits a safety engineer balancing design innovation with regulatory obligation — mapping hundreds of hazards to harmonized standards such as ISO 10218, ISO 13849, and IEC 60204. It’s critical work, but often done manually across disconnected spreadsheets and documents — slow, error-prone, and difficult to maintain across iterations.

Reimagining Compliance Through AI

Saphira was built to modernize this process. Our AI-powered platform helps manufacturers, system integrators, and risk engineers automate hazard discovery, standards mapping, and CE Marking validation — turning a reactive documentation task into a continuous, intelligent process.

Here’s how it works:

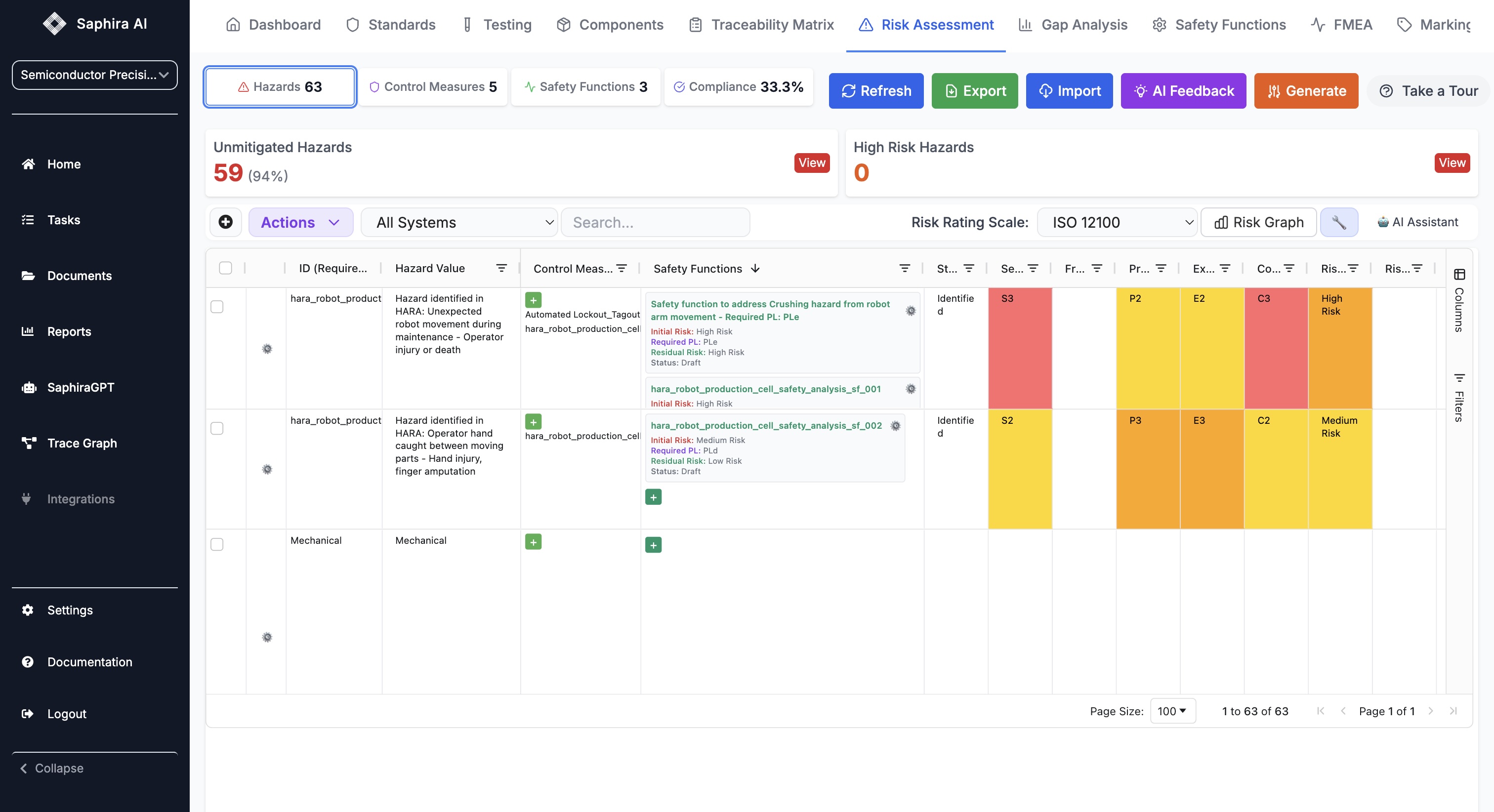

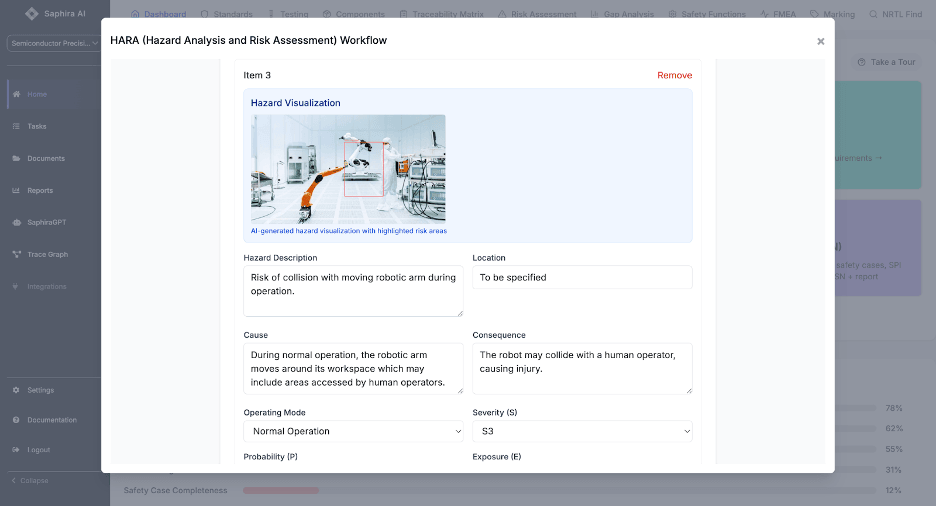

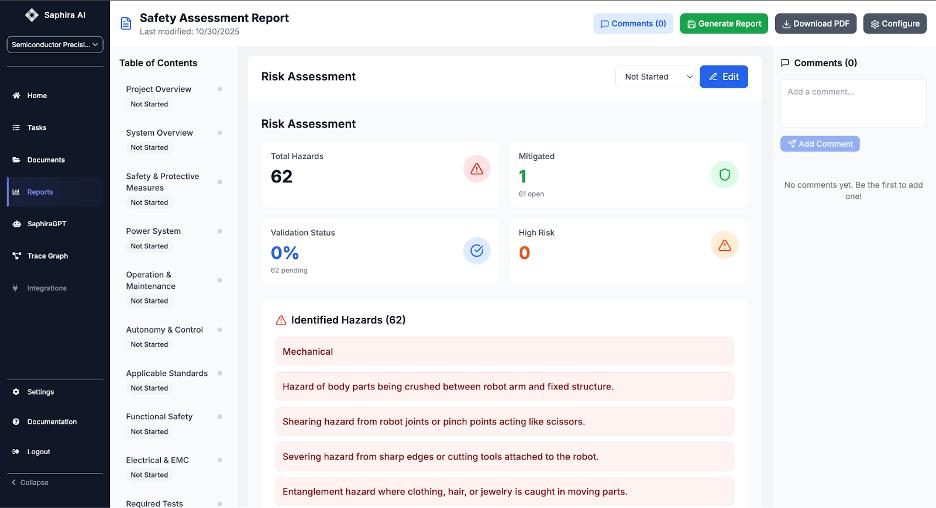

1. AI-Based Hazard Identification

Saphira analyzes design data and control logic to automatically identify potential hazards — mechanical, electrical, control, and human-interaction risks.

Visual: Example hazard detection table showing risk categories.

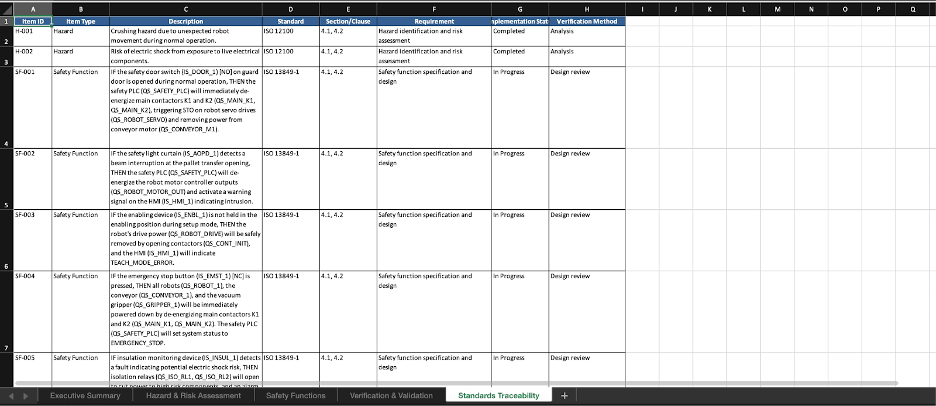

2. Automated Standards Mapping

Each hazard and corresponding safeguard is mapped to relevant clauses from harmonized standards such as ISO 10218, ISO 13849, and IEC 60204. This establishes a clear, clause-level traceability path between design intent and compliance requirement.

Visual: Standards Mapping screenshot showing hazard → clause linkages.

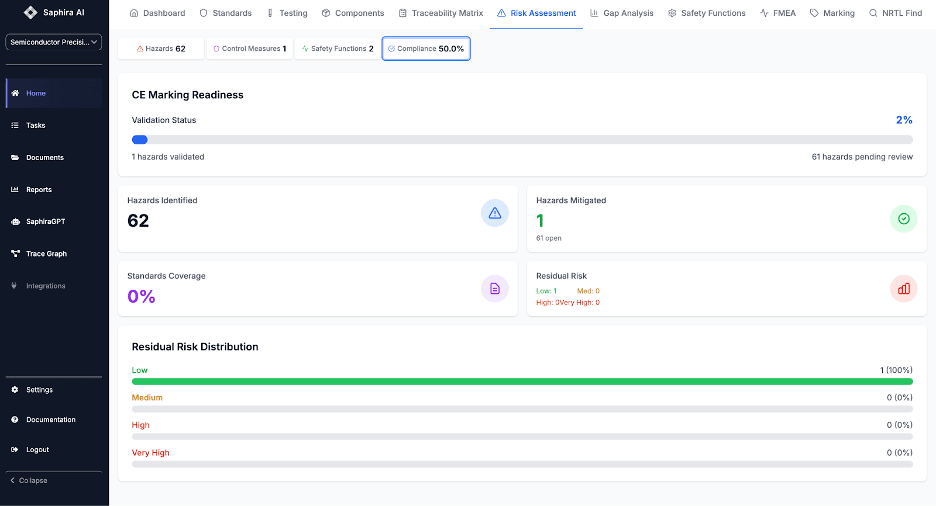

3. Validation Dashboard

A real-time compliance dashboard tracks CE readiness, residual risk levels, and mitigation progress across subsystems. Teams can see which parts of the system remain under review and which are validated.

Visual: Dashboard view with progress metrics or compliance heatmap.

4. Technical File Generation

Finally, with a single click, Saphira assembles the technical documentation required for CE Marking — including the risk assessment, standards matrix, and validation evidence.

Visual: Export dialog or generated technical file preview.

Adoption Across Manufacturing Sectors

Leading manufacturers in the aerospace and automotive sectors have already adopted Saphira to accelerate risk and compliance activities across their robotic production lines.

By shifting from static spreadsheets to structured, AI-assisted analysis, teams have been able to:

- Reduce manual effort in risk assessments by more than 60%

- Improve coordination between mechanical, controls, and safety engineers

- Achieve faster internal reviews and technical documentation cycles

These improvements aren’t just about efficiency — they enhance traceability, consistency, and confidence in every CE submission.

A Shared Challenge Across Industries

Whether a robotic cell is installing fasteners, painting surfaces, or performing precision handling, the challenge is the same:

- Identify hazards early

- Validate safety functions

- Prove compliance across multiple overlapping standards

Saphira provides a single digital workspace to manage all of it — aligning engineering data with compliance requirements in real time.

This unified approach helps ensure that safety is not a checklist at the end of a project but a living, verifiable part of system design.

Looking Ahead

As industrial automation continues to evolve, so will the expectations of regulators and auditors. The future of compliance will be intelligent — with AI systems not only assisting engineers but helping validate that each safety claim is backed by data and traceable evidence.

Saphira represents a step toward that future:

- Structured, interpretable, and AI-assisted risk analysis

- Clause-level traceability to harmonized standards

- Continuous monitoring of CE Marking readiness

For robotics and industrial machinery teams, that means faster compliance, better collaboration, and higher safety assurance — without sacrificing innovation.

If you’ll be at A3 IRSC this week, come see how Saphira is redefining how risk and compliance come together in automation.

Learn more at www.saphira.ai